My Lavender Soap Recipe

A lovely lavender soap recipe, made simple!

Print

Pin

Yield (adjustable): 6 bars

Ingredients:

Oils

- 291 g (10.26 oz) Olive Oil

- 112 g (3.95 oz) Coconut Oil

- 22 g (0.78 oz) Castor Oil

- 25 g (0.88 oz) Cocoa Butter

Lye Solution

- 63.5 g (2.24 oz) Soapmaking Lye

- 127 g (4.48 oz) Distilled Water

Aromatics & Botanicals

- 14 g (0.49 oz) Lavender Essential Oil

- 1 tbsp (0.03 pt) Cornflower Petals

Equipment:

- Large plastic /glass jug or plastic bucket.

- Silicone Soap Mold (Note: Ingredients are for 1/2 Loaf Mold)

- Spoon or Spatula ideally both

Instructions:

Prep Work

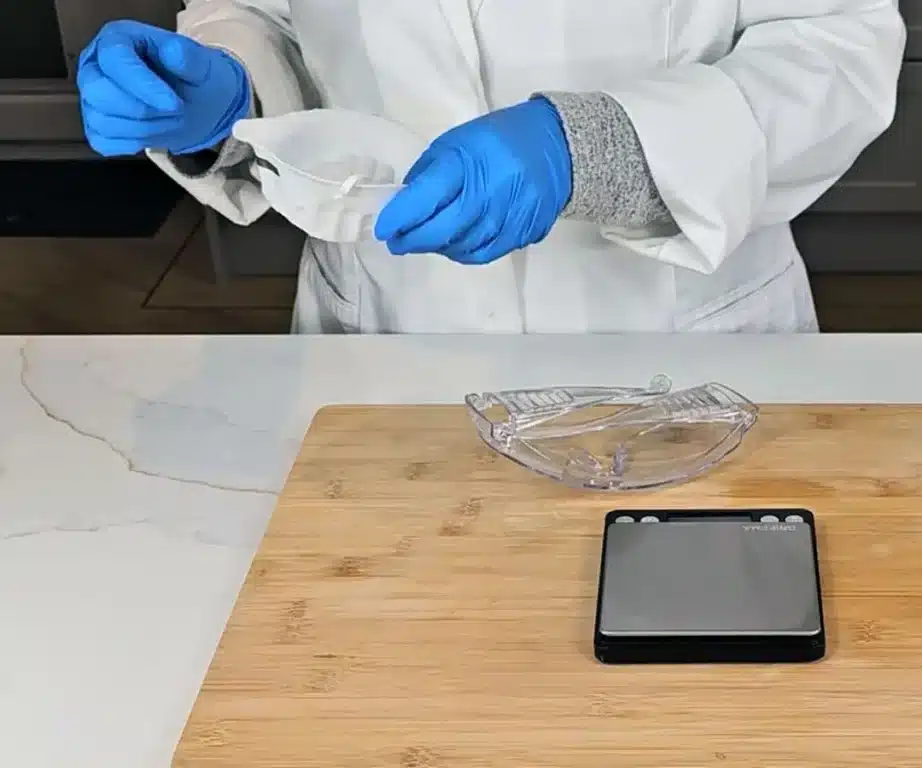

- It helps to preweigh all of your ingredients beforehand. I would recommend to at least weigh your essential oils now, to avoid wasting time when your batter reaches trace. Set it aside for later useIMPORTANT: Make sure you are making the soap in a well-ventilated area. Put on your gloves and eye protection, mask, apron, and long rubber gloves.

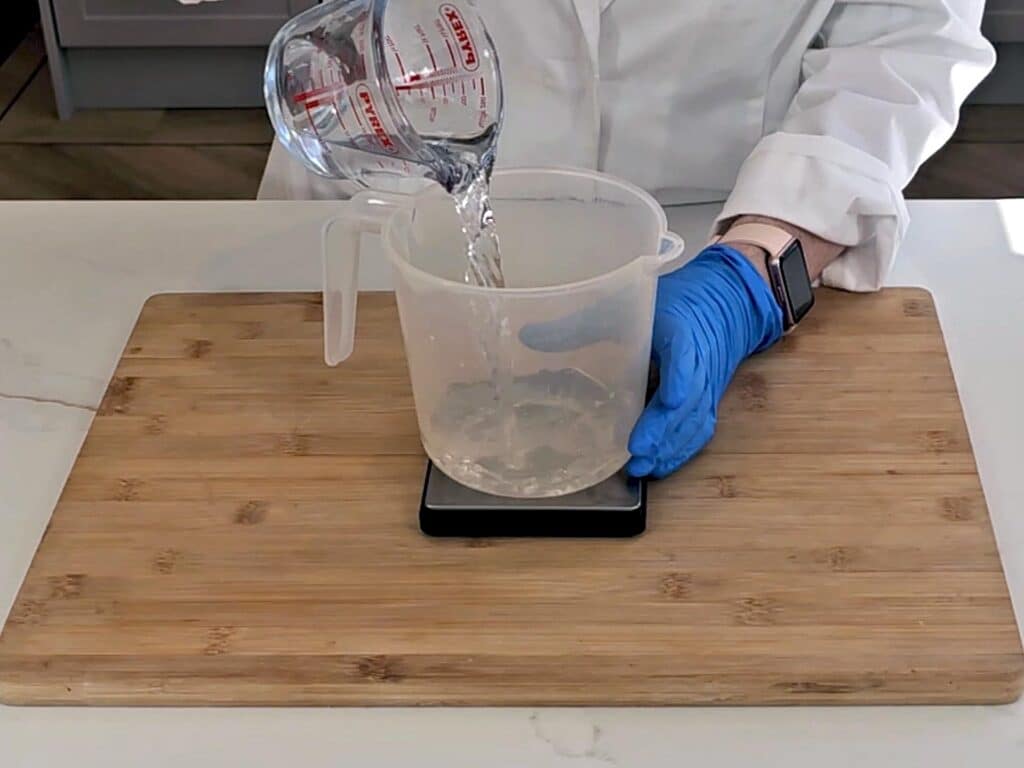

Making The Lye Solution

- Weigh the distilled water into a clean container. Never use a glass container as this will be holding the lye water. Lye can weaken glass so it can easily break. In a separate container, weigh your sodium hydroxide/lye crystals.127 g Distilled Water, 63.5 g Soapmaking Lye

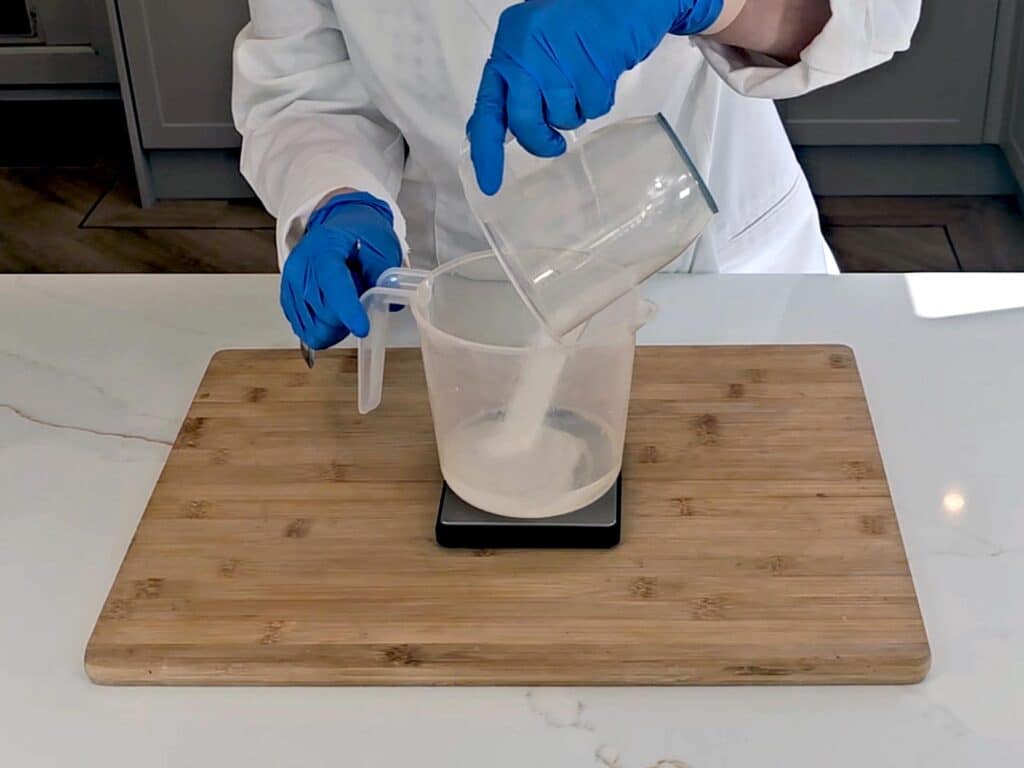

- When you’re ready, carefully pour your lye crystals into the water, do not pour the water into the lye as this can create a violent reaction.When the lye is in the water, start stirring it. Although you are wearing a mask, we still recommend turning your head and leaning away while stirring, so you do not breathe any of the fumes. As the water and lye mix this will result in a chemical reaction, and the lye water will increase in temperature and release toxic fumes.

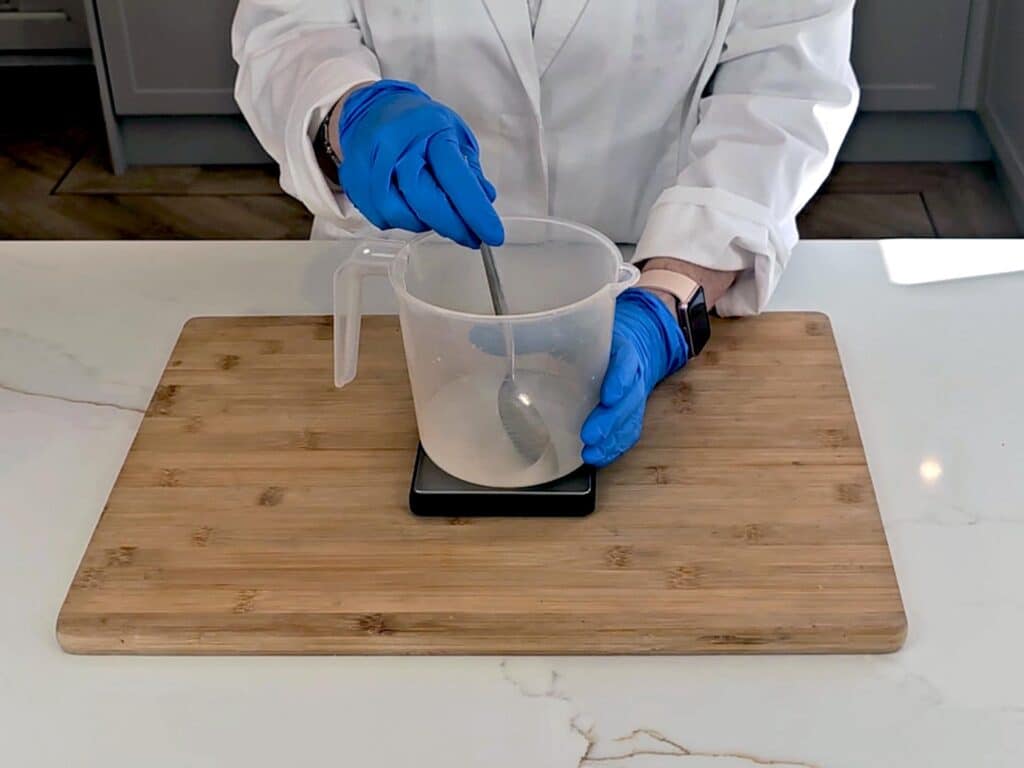

- Stir until the lye crystals have dissolved and the water looks fairly clear. Now place to one side, somewhere well-ventilated but safe so that it will not be knocked over. Allow to cool as we get on with our other steps.

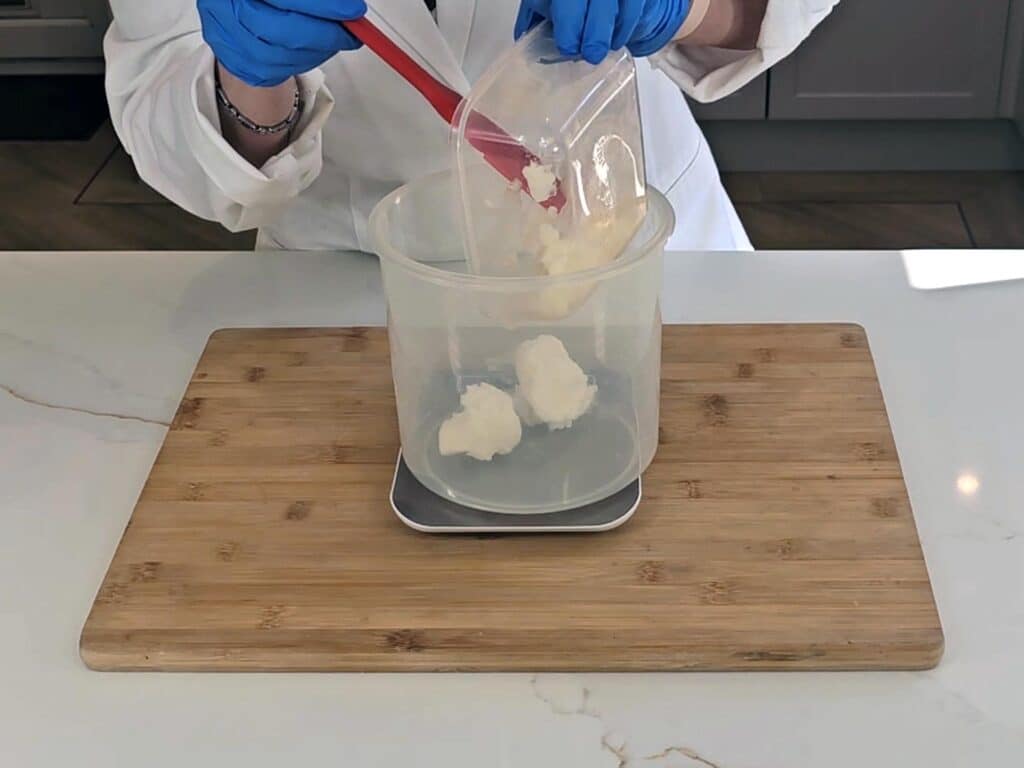

Preparing Our Oil Phase

- If you haven't already, weigh the coconut oil and cocoa butter into a good-sized heatproof container. Then, melt in a microwave, using 30-second bursts. Or in a stainless steel saucepan on a low heat.112 g Coconut Oil, 25 g Cocoa Butter

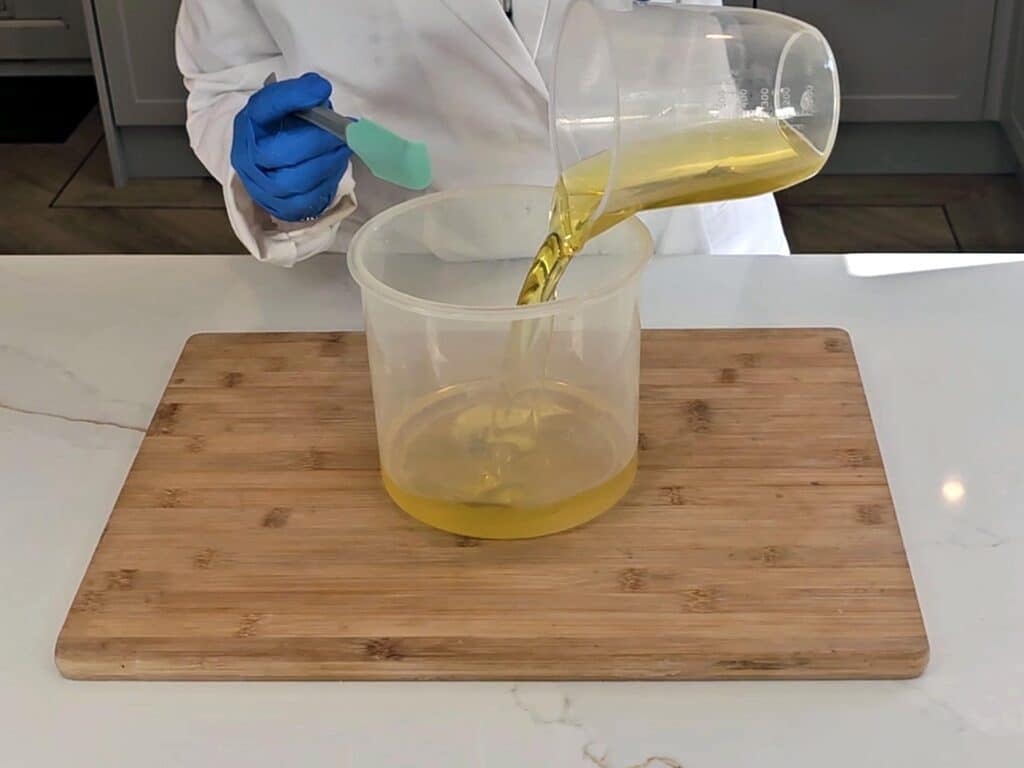

- Once melted, add the olive oil and castor oil then give it a quick stir. You should now have all your oils in a liquid state all in one good-sized bowl or saucepan.291 g Olive Oil, 22 g Castor Oil

Balancing & Mixing

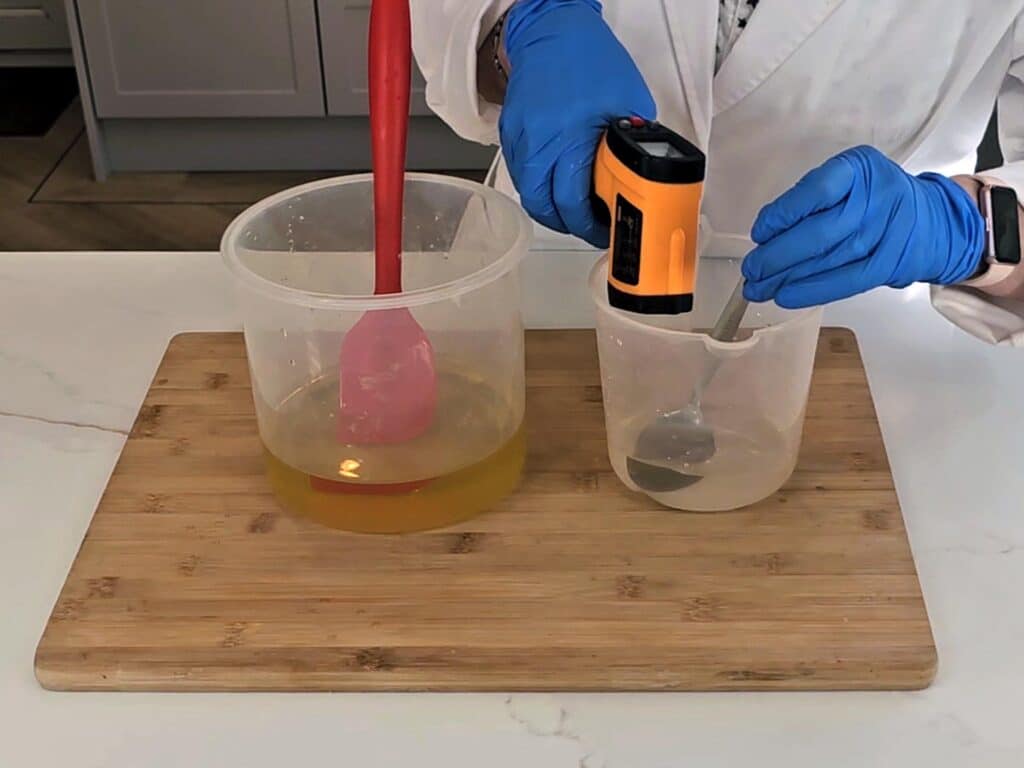

- Check the temperature of the oils and the lye water. You can do this with a temperature laser gun or a jam thermometer. We want them both to fall between 115-80F (46-27C). If they are still too hot leave them to cool for a while longer. They do not need to be the same temperature, for example, the lye could be 90f and oils 100f, but it is best to keep them within 10 degrees of each other.

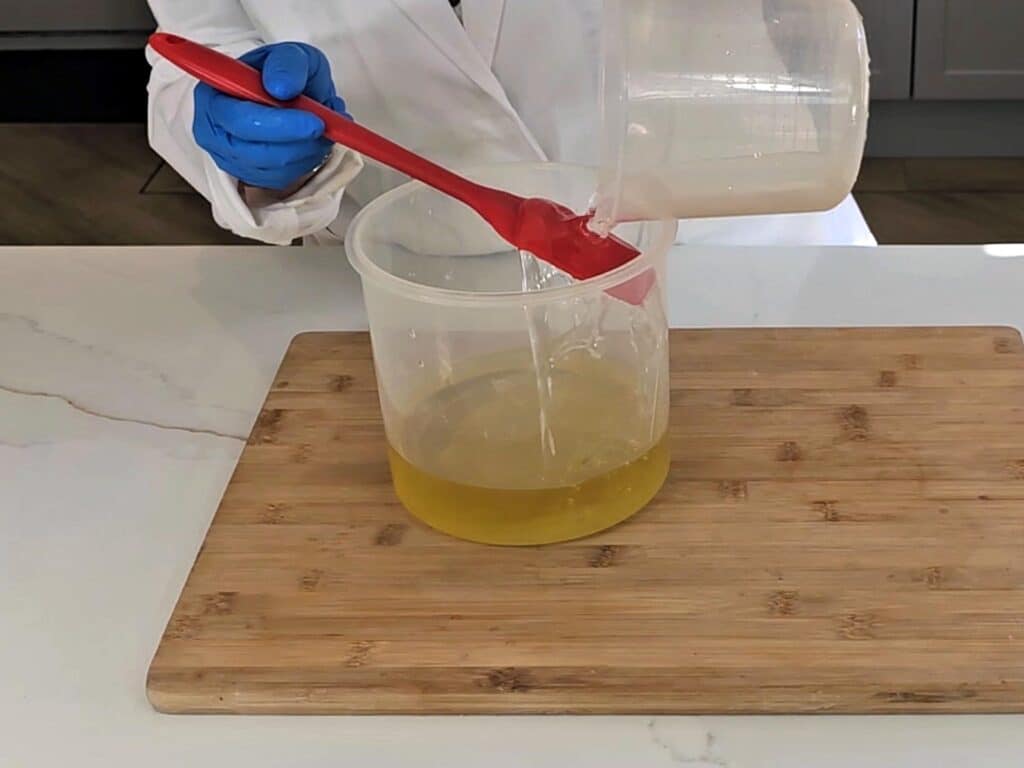

- Once you’re satisfied they’re balanced, pour your lye solution into your oils.

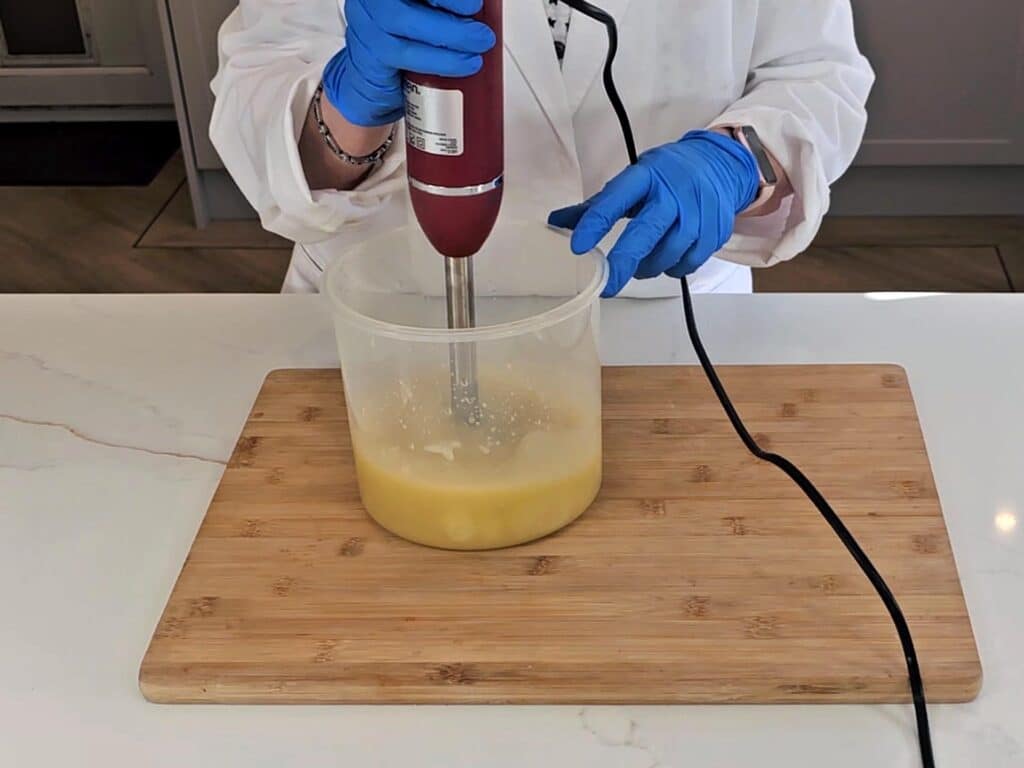

Blending To Trace

- Before turning on the stick blender to mix the oils and lye, gently tap the stick blender against the bottom of your container. Continue tapping until all the air bubbles have been released. Then, turn on the stick blender and blend until the oils are fully emulsified into the lye solution. Then switch off the blender and check for trace. This is when you can drizzle a small amount of soap batter on top and it leaves a visible trail or 'trace' on the surface.

Adding Our Aromatics

- Now that we’re at trace, it’s time to add our essential oils. After adding them, stir well so they are fully combined into the soap batter. I always recommend having the mold ready before adding the essential oils. This is because EOs can sometimes thicken the soap batter, meaning you have to work quickly to get it into the mold.14 g Lavender Essential Oil

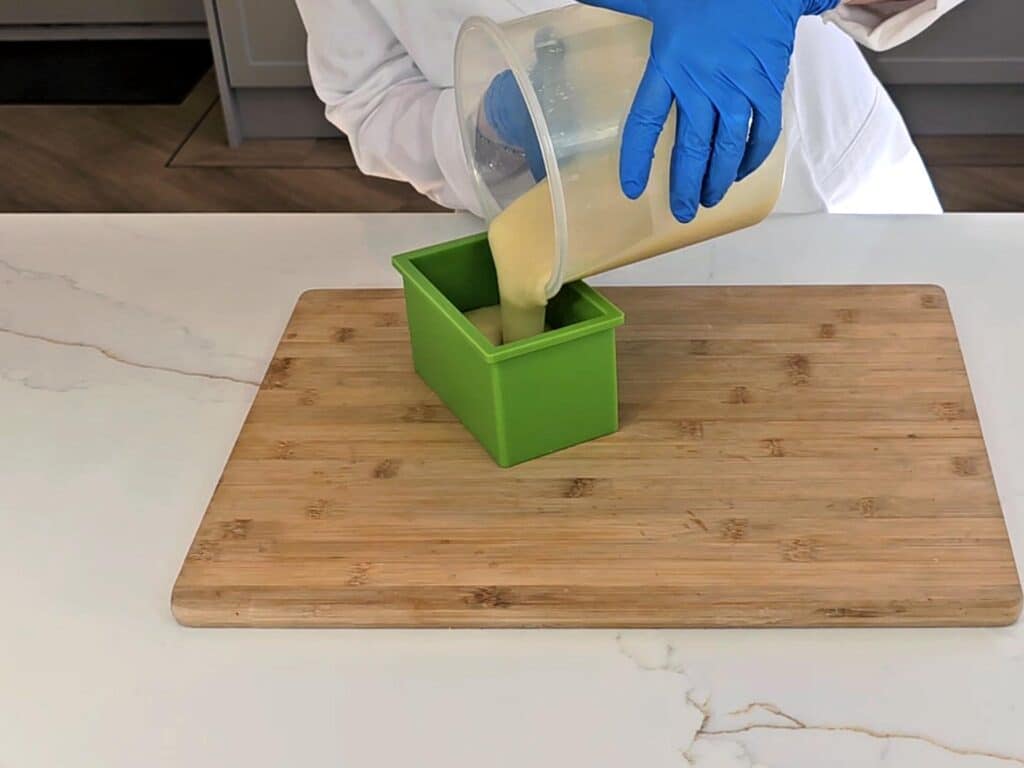

Pouring Into The Mold

- Now it’s time to get it into the mold. Pour or spoon the batter into your loaf mold. Give it a couple of light taps down to even the soap batter out, and use a silicon spatula to level it out if needed.

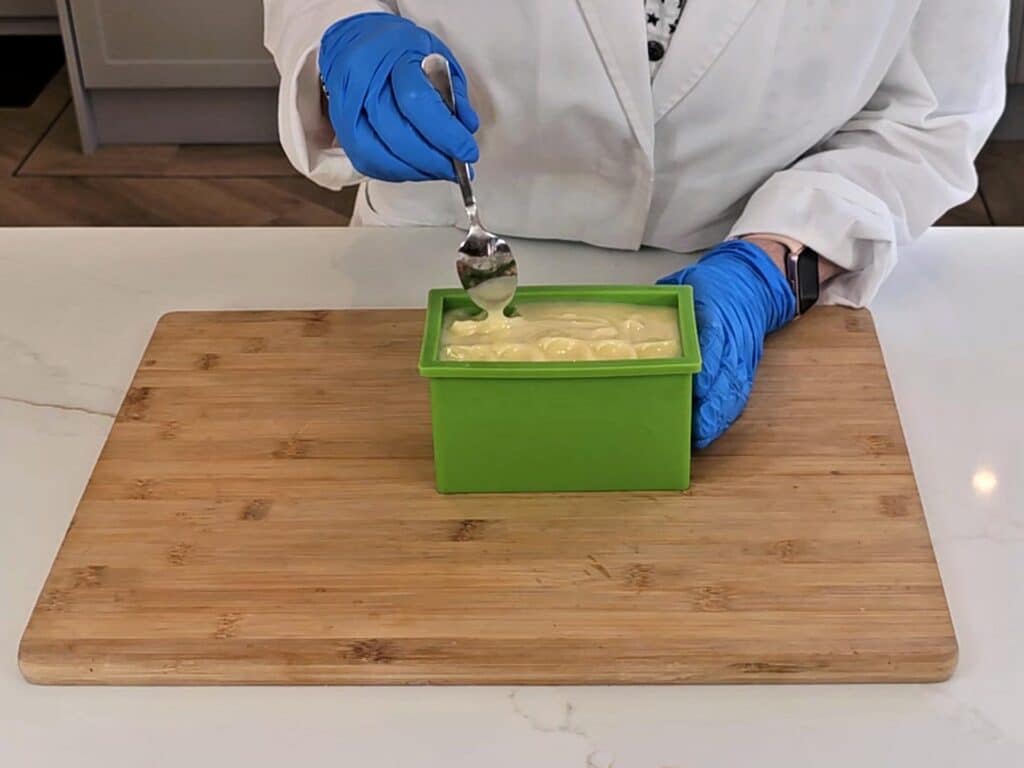

- You can leave the top of the soap flat or add some texture with a spoon. Adding texture is a great way to conceal any uneven flaws, and can make the soap interesting. You can also top with flowers.1 tbsp Cornflower Petals

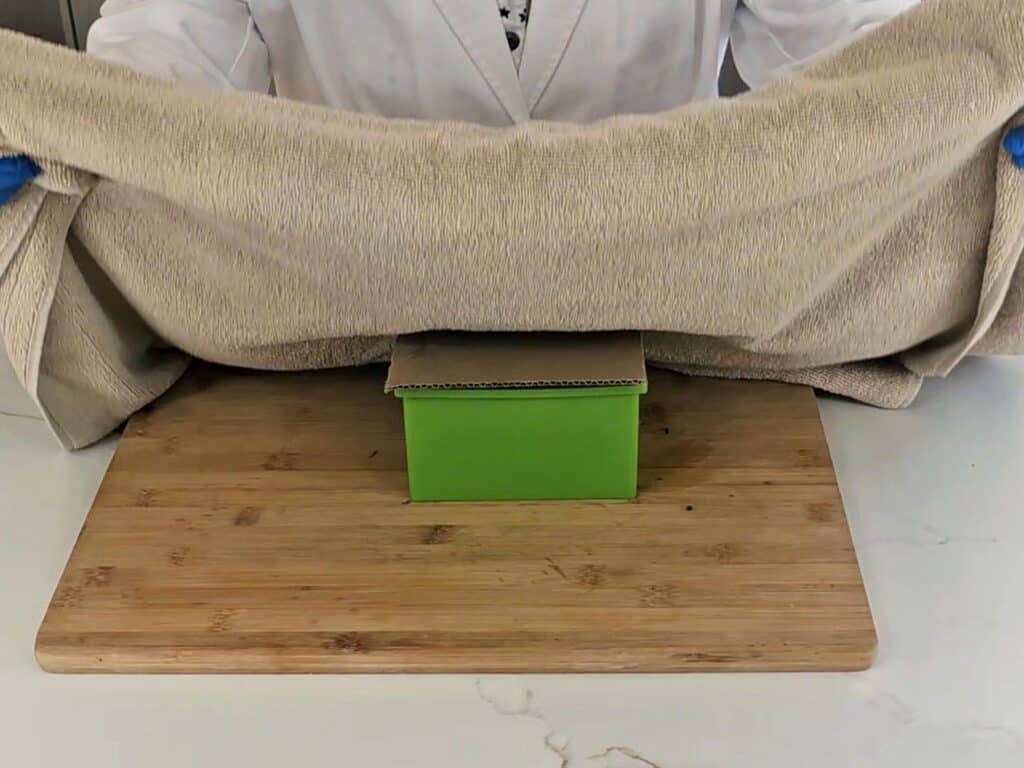

- We now need to leave this to saponify for 24-48 hours before we can remove it from the mold. I like to keep it well insulated during this period, so the gel phase is efficient. I do this by cutting a piece of cardboard to sit on top of the mold and then covering it with an old towel.

- Once our soap has fully saponified, and the sides of the mold come away easily from the soap, it’s okay to remove it from the mold.

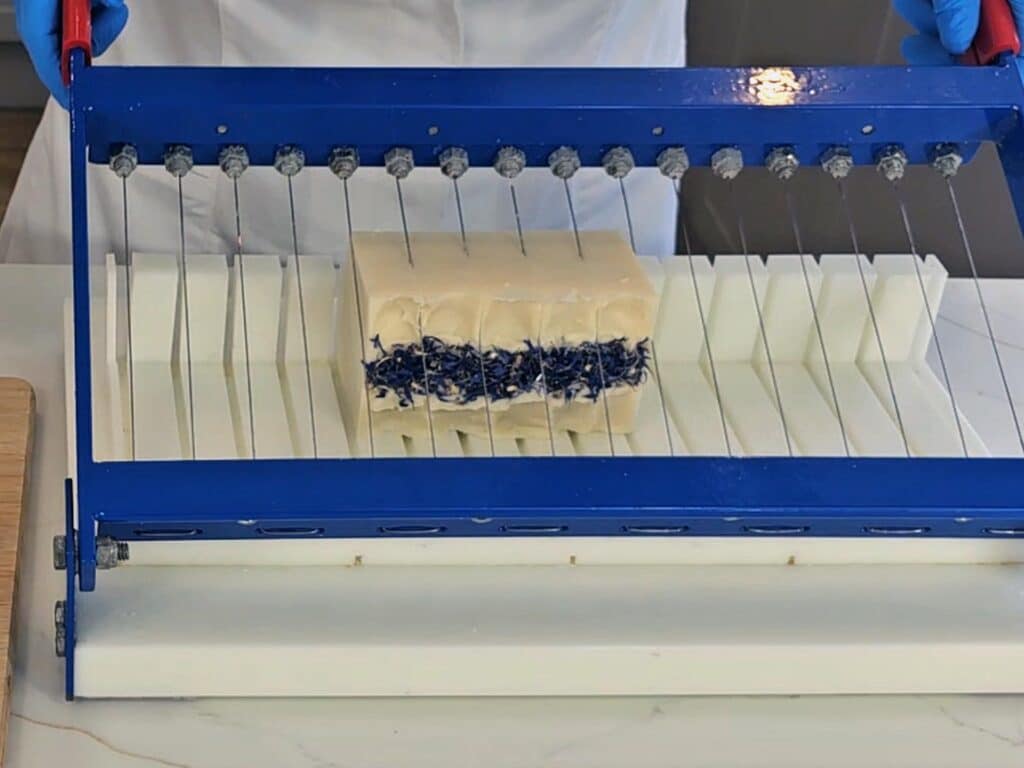

- Now it's time to cut the soap loaf into bars. This can be done using a soap cutter or a sharp knife. You should get between 5 or 6 bars, depending on how thick you cut them.The soap will need to cure for 4 to 6 weeks before using. Curing the soap allows excess water to evaporate, resulting in a harder, longer lasting bar. This also results in a more gentle bar and a better lather.

Tried this projectMention @Savvyhomemade or tag #savvyhomemade!